In the world of modern metal product manufacturing, technology plays a crucial role, and one of the most impressive metalworking techniques is sheet metal rolling. This method allows for the creation of complex products that incorporate various bending radii, bringing designer fantasies to life. Let's discuss what it is, why it is needed, where and when it is used, as well as the advantages of this remarkable technology.

WHAT IS SHEET METAL ROLLING?

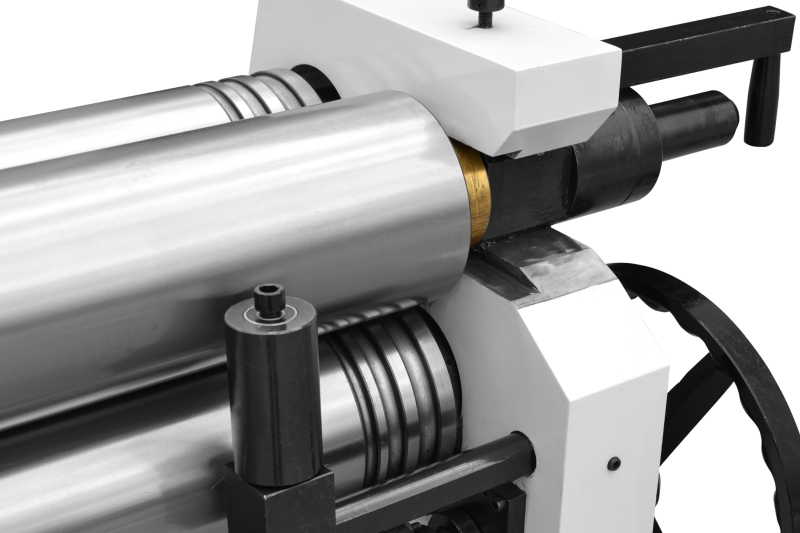

Sheet metal rolling is a technological process in which a flat sheet of metal is subjected to the action of special rolls and press forms. This enables the achievement of complex geometric shapes, creating products with various bends and radii. Manipulating metal in this way opens doors to manufacturing unique and functional items.

Why is sheet metal rolling needed?

Sheet metal rolling has a wide range of applications in various industries, including automotive manufacturing, aviation, shipbuilding, construction, and even art. This process allows for the creation of structural elements, fairings, bodies, enclosures, and many other parts that require complex shapes and design flexibility.